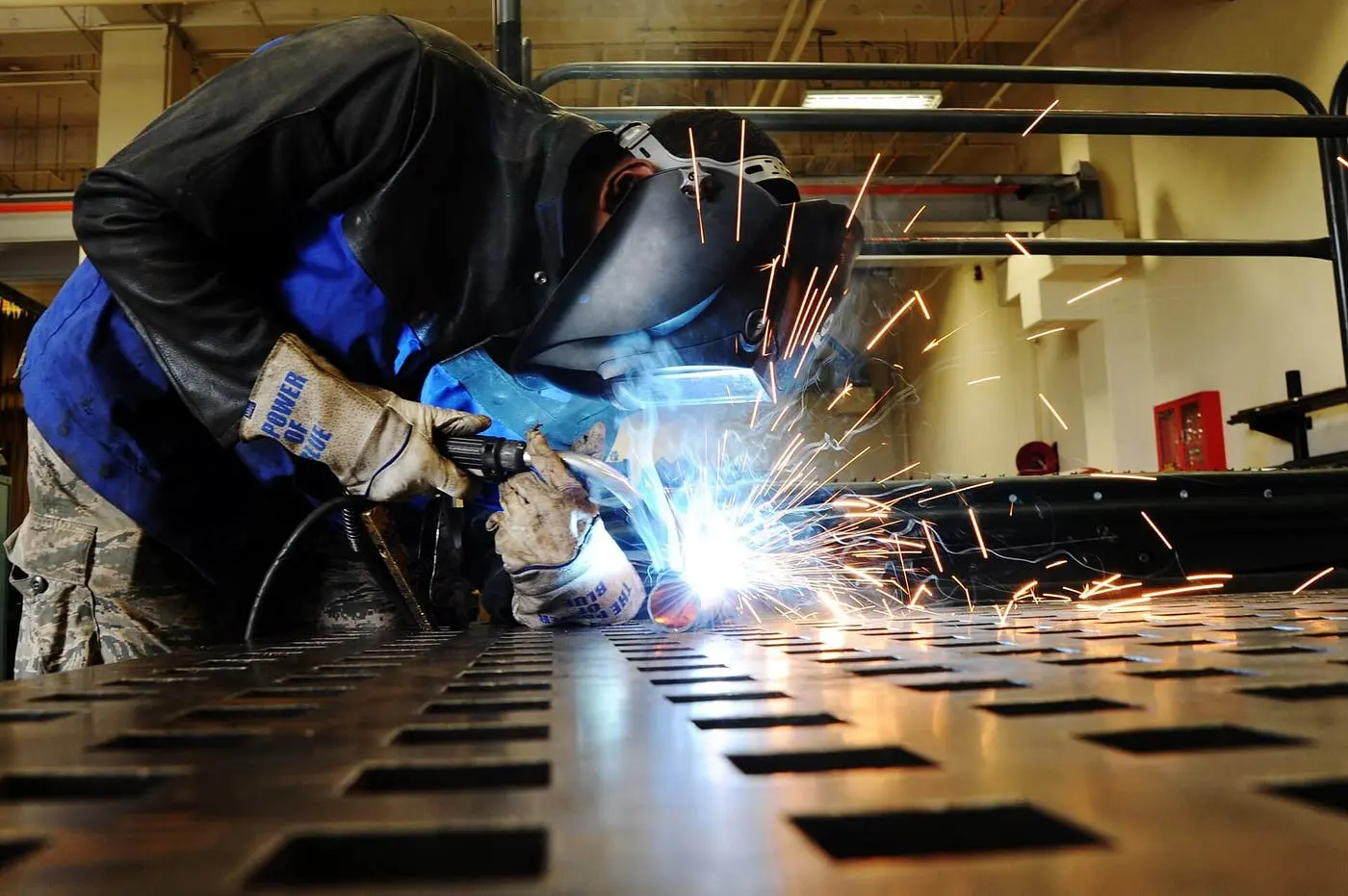

Sheet metal fabrication requires precision and skill, and having access to the right tools is crucial for achieving excellent results. That’s why professionals in the industry flock to Metal Event Showcases, where they can explore a wide range of versatile sheet metal tools tailored to their specific needs and preferences. These showcases provide a comprehensive overview of the latest advancements in cutting, bending, and specialized equipment, ensuring that attendees are equipped with the perfect tools for their projects.

Whether you’re a seasoned professional or just starting out, the Metal Event Showcases offer a platform for discovering your ideal sheet metal tools and staying at the forefront of industry innovation.

Don’t miss out on the opportunity to find tools that will take your sheet metal fabrication to the next level. Join us at Metal Event Showcases and unlock a world of possibilities for your craft.

Key Takeaways

- Versatile sheet metal tools are essential for shaping, cutting, and bending sheet metal, allowing for intricate designs and complex shapes.

- These tools contribute to increased productivity and cost-effectiveness, maintaining high-quality standards and consistent results.

- Factors to consider when choosing sheet metal tools include the type of sheet metal, the specific task, size and thickness of the sheet metal, precision and accuracy requirements, and budget and support.

- Different types of cutting tools, bending tools, and joining tools provide various options for sheet metal fabrication.

Importance of Versatile Sheet Metal Tools

The importance of versatile sheet metal tools cannot be understated in the world of metalworking. These tools play a crucial role in shaping, cutting, and bending sheet metal to create a wide range of products. They provide the necessary precision and efficiency required for various tasks, making them indispensable for professionals in the industry.

Versatile sheet metal technology offer a range of capabilities that allow metalworkers to achieve intricate designs and complex shapes. With these tools, they can easily cut through thick sheets of metal, create smooth curves, and produce precise angles. This versatility enables metalworkers to meet the diverse needs of their clients and tackle a wide range of projects.

Furthermore, versatile sheet metal tools contribute to increased productivity and cost-effectiveness. By having access to a variety of tools that can handle different tasks, metalworkers can streamline their workflow and complete projects more efficiently. This not only saves time but also reduces the need for additional equipment, resulting in cost savings for both the metalworker and the client.

In addition, using versatile sheet metal equipments allows metalworkers to achieve consistent results and maintain high-quality standards. These tools are designed to provide accurate measurements and precise cuts, ensuring that every piece of sheet metal is shaped exactly as intended. This level of precision is crucial in industries such as aerospace and automotive, where even the slightest error can have significant consequences.

Key Features to Look for in Sheet Metal Tools

With an understanding of the importance of versatile sheet metal tools in the metalworking industry, it is essential to explore the key features that professionals should look for when selecting these tools. Sheet metal tools are crucial for fabricating and manipulating various metal materials, and choosing the right tools can greatly impact the efficiency and quality of the work.

One key feature to consider is the durability and strength of the tool. Sheet metal tools need to withstand the rigorous demands of metalworking tasks, such as cutting, bending, and forming. Look for tools made from high-quality materials, such as hardened steel, that can withstand heavy use without wearing down or breaking.

Another important feature is the precision and accuracy of the tool. Sheet metal work requires meticulous attention to detail, so it is crucial to choose tools that can provide precise and accurate measurements, cuts, and bends. Look for tools with clear and easy-to-read measurement markings, as well as adjustable features that allow for precise adjustments.

Ergonomics is also an important consideration. Sheet metal work often involves repetitive tasks, so it is important to choose tools that are comfortable to use for extended periods. Look for tools with ergonomic handles that provide a comfortable grip and reduce strain on the hands and wrists.

Lastly, consider the versatility of the tool. Different sheet metal projects may require different tools and techniques, so it is beneficial to choose tools that can perform multiple functions. Look for tools with interchangeable blades or attachments that can adapt to different tasks and materials.

How to Choose the Right Sheet Metal Tool for Your Project

To select the appropriate sheet metal tool for your project, carefully consider the specific requirements and demands of the task at hand. Choosing the right tool is crucial as it can significantly impact the quality and efficiency of your work. Here are some key factors to consider when making your decision.

Firstly, analyze the type of sheet metal you will be working with. Different metals require different tools and techniques. For example, stainless steel may require a different cutting tool compared to aluminum. Understanding the characteristics of the metal will help you choose the right tool that can effectively handle it.

Secondly, consider the specific task you need to accomplish. Are you cutting, bending, or shaping the sheet metal? Each task requires a different tool. For cutting, options include shears, nibblers, or plasma cutters. Bending can be achieved with tools like brake presses or folding machines. Shaping may require specialized tools such as bead rollers or English wheels.

Additionally, take into account the size and thickness of the sheet metal. Some tools are better suited for thin gauge sheets, while others are designed for thicker materials. Ensure that the tool you choose can handle the specific dimensions and thickness of your project.

Furthermore, consider the precision and accuracy required for your task. Some tools offer more control and precision than others. For intricate or detailed work, you may need tools that provide fine adjustments and precise measurements.

Lastly, budget and availability are important considerations. Determine your budget and research the various options available within your price range. Consider the availability of spare parts, accessories, and technical support for the chosen tool.

Exploring Different Types of Versatile Sheet Metal Tools

Exploring a variety of versatile sheet metal systems is essential for any metalworker looking to enhance their craftsmanship and efficiency. By understanding the different types of sheet metal tools available, metalworkers can choose the appropriate tool for their specific projects, ensuring accurate and precise results.

Here are three sub-categories of versatile sheet metal tools to consider:

- Cutting Tools:

- Shears: Used for straight cuts in sheet metal, shears come in various sizes and can handle different thicknesses of metal.

- Nibblers: Ideal for cutting intricate shapes, nibblers use a punching and die system to create precise cuts with minimal distortion.

- Plasma Cutters: These tools use a high-velocity jet of ionized gas to cut through various metals, providing clean and precise cuts.

- Bending Tools:

- Brake Press: A versatile tool for creating bends, a brake press uses a clamp and die system to accurately bend sheet metal to the desired angle.

- Rollers: Designed to create curved or cylindrical shapes, rollers use a set of rollers to gradually shape the metal into the desired form.

- Bead Rollers: Used for adding strength and decorative elements to sheet metal, bead rollers create raised or indented patterns along the metal’s surface.

- Joining Tools:

- Spot Welders: These tools use an electrical current to join two or more pieces of metal together quickly and securely.

- Rivet Guns: Ideal for fastening two or more pieces of metal, rivet guns use a pulling mechanism to secure rivets in place.

- Seamers: Seamers are used to join two pieces of sheet metal together by creating a folded seam, ensuring a strong and permanent bond.

Maximizing Efficiency and Quality With Versatile Sheet Metal Tools

After exploring the different types of versatile sheet metal tools, it is essential for metalworkers to understand how to maximize efficiency and quality when using these tools. By employing the right techniques and strategies, metalworkers can ensure that they are getting the most out of their tools and producing high-quality results.

One way to maximize efficiency is by properly maintaining and caring for the sheet metal tools. Regular cleaning and lubrication can help prevent rust and corrosion, ensuring that the tools operate smoothly and efficiently. Additionally, sharpening blades and replacing worn-out parts can greatly improve the performance of the tools and reduce the time and effort required to complete tasks.

Metalworkers should also familiarize themselves with the different features and capabilities of their sheet metal tools. By understanding the tool’s limitations and strengths, they can make informed decisions about which tools to use for specific tasks. This knowledge allows them to work more efficiently and achieve better results.

Moreover, metalworkers should invest in high-quality sheet metal tools. While they may be more expensive upfront, these tools are often more durable and reliable, resulting in less downtime due to repairs or replacements. High-quality tools also tend to have better precision and control, allowing for more accurate and consistent work.

Frequently Asked Questions

What Are Some Common Types of Versatile Sheet Metal Tools?

Some common types of versatile sheet metal tools include shears, snips, and nibblers for cutting, bending brakes for forming precise angles, and seaming pliers for joining pieces together. These tools are essential for various sheet metal fabrication tasks.

How Can Versatile Sheet Metal Tools Improve Efficiency and Quality in Projects?

Versatile sheet metal tools can greatly improve efficiency and quality in projects. Their ability to perform multiple functions and adapt to different tasks allows for faster completion times and more precise results.

What Are Some Key Features to Consider When Choosing Sheet Metal Tools?

When choosing sheet metal tools, key features to consider include durability, versatility, precision, and ease of use. These factors will ensure efficient and high-quality results in various projects, maximizing productivity and minimizing errors.

Are There Any Specific Factors to Consider When Choosing Sheet Metal Tools for a Particular Project?

When choosing sheet metal tools for a particular project, it is important to consider factors such as the type of material, the complexity of the design, the required precision, and the desired output. These factors will help determine the most suitable tools for the job.

Where Can I Find Metal Event Showcases to Discover My Sheet Metal Tool Preference?

Metal event showcases are the ideal platform to discover your sheet metal tool preference. These showcases provide an opportunity to explore a wide range of versatile sheet metal tools and learn about their features and applications.

Conclusion

In conclusion, attending Metal Event Showcases provides professionals in the sheet metal fabrication industry with the opportunity to discover and explore a diverse range of versatile sheet metal tools. By understanding the importance of versatile tools and considering key features, individuals can choose the right tool for their specific projects. With the knowledge gained from these showcases, professionals can maximize efficiency and quality in their work, ensuring precision and success in sheet metal fabrication.

You May Also Like: